At beadedstream, innovation drives us to constantly improve our products to meet the needs of our customers. Our latest advancement, the stainless steel rigid temperature probe, is a testament to this commitment. This new probe offers significant improvements over traditional acrylic probes, particularly in terms of durability, thermal responsiveness, and overall performance. In this blog post, we will explore the development, testing, and advantages of the stainless steel rigid probe, along with its practical applications.

The Evolution of Temperature Probes

Pavement and road-base temperature monitoring has long relied on acrylic probes due to their affordability and ease of manufacturing. However, field use revealed several limitations, particularly in harsh environments. Acrylic probes often faced challenges such as breakage during retrieval from frozen ground and chemical degradation when exposed to harsh substances.

In our quest to develop a more robust solution, we drew inspiration from our Snow Depth Monitor probe. The stainless steel construction used in these probes proved to be far more resilient and effective. This realization led us to re-engineer our temperature probes using stainless steel, resulting in a product that not only withstands extreme conditions but also enhances data accuracy and reliability.

Rigid Probe: Acrylic vs. Stainless Steel Testing

To ensure the new stainless steel probes met our high standards, we conducted a series of rigorous tests comparing them to our traditional acrylic probes. Our testing regimen included submerging both probes side by side in an ice bath for extended periods, subjecting them to various conditions (See Fig. 2). The results were promising:

- Thermal Responsiveness: The stainless steel probe demonstrated quicker response times to external temperature changes compared to the acrylic probe, being 31% faster at reaching ice bath temperature from air temperature (See Fig. 3). This rapid responsiveness ensures more accurate and timely data collection, a critical factor in dynamic environments such as monitoring road and sea ice temperature profiles.

- Heat Conduction: The stainless steel probe showed that each sensor was more coupled to its environment outside the probe horizontally than vertically. This resulted in less heat transfer being detected between adjacent sensors on the probe. This characteristic is vital for applications requiring precise thermal measurements.

- Steady-State Accuracy: Both the stainless steel and acrylic probes provided consistent results at steady-state temperatures. This means that the new probes can seamlessly replace older models without compromising data integrity.

Advantages of Stainless Steel Probes

The transition to stainless steel probes brings several key benefits:

- Durability and Ruggedness: Stainless steel is inherently more durable than acrylic. This makes the probes more resistant to physical stress, such as the forces encountered during retrieval from frozen ground. The robust construction also ensures longevity and reliability in harsh conditions.

- Chemical Compatibility: Stainless steel can withstand exposure to a wide range of chemicals without degrading. This expands the applicability of the probes to environments where acrylic would fail, such as areas with diesel contamination or other corrosive substances.

- Improved Thermal Characteristics: The thermal conductivity of stainless steel allows for faster and more accurate temperature readings. This is particularly important in environments with rapid temperature fluctuations, where timely data is crucial.

- Ease of Assembly: The manufacturing process for stainless steel probes is more streamlined, resulting in faster lead times.

- Smaller Diameter: The stainless rigid probe is ½” diameter compared to the acrylic probe diameter of 1”. A smaller diameter means less of an impact on the environment being measured.

Practical Applications

The stainless steel rigid probe is ideal for collecting temperature data with sensor spacing as close as every 2.5 cm (1 inch). Its solid, waterproof, and frost-resistant design makes it suitable for various applications, including:

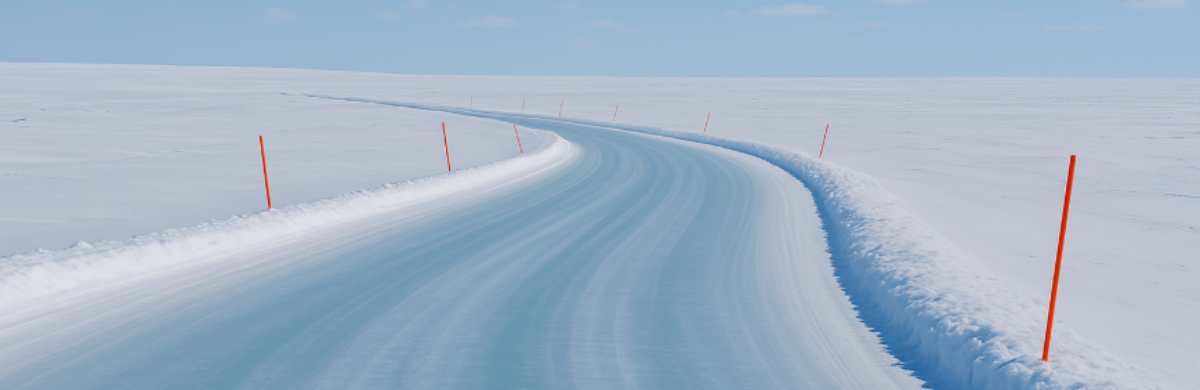

- Road Weather Information Systems (RWIS): The probes are ideal for monitoring road subgrade temperatures, providing critical data for weather forecasting and road maintenance.

- Near-Shore Sea Ice Monitoring: Their submersible and frost-resistant design makes them perfect for marine environments.

- Pond and Streambed Temperature Monitoring: The probes can be customized up to six feet (1.8m) in length, making them suitable for shallow aquatic settings.

- Pavement Sections: Customizable lead lengths allow for precise installation in pavement sections, enhancing the probe’s versatility.

Conclusion

The development of the stainless steel rigid probe marks a significant milestone in temperature monitoring technology. By addressing the limitations of acrylic probes and enhancing performance, we have created a product that meets the demanding needs of our customers. The stainless steel rigid probe merges innovative digital technology with proven temperature node configuration, ensuring high-quality, reliable data collection for various applications.

At beadedstream, we are dedicated to continuous product enhancement to offer our customers optimal solutions. For more details about our new stainless steel rigid probes or to witness their performance, please visit the webpage for rigid probe or reach out to our technical sales team at contact@beadedstream.com.