For industries operating in the Arctic—particularly mining and oil & gas—winter ice roads are critical for transporting personnel, equipment, and supplies. However, climate change is rapidly shortening their lifespan, increasing logistical challenges, costs, and safety risks. Research published in Nature shows that potential ice road days (PIRDs) in the Canadian Arctic are decreasing by 10.17 days per decade, with some regions projected to lose up to 8% of their ice road availability by 2035.

To adapt, mining and energy companies must move beyond traditional assumptions and rely on real-time temperature monitoring to make data-driven decisions.

The Growing Challenge: Shorter Ice Road Seasons and Rising Risks

Arctic ice roads often require a minimum thickness of 70 cm (28 inches) for safe transport, but rising temperatures are significantly shortening their seasons. In northern Alaska, tundra road openings have shifted nearly two months later—from early November (pre-1991) to January in recent years, cutting valuable operating time, and increasing reliance on costly air transport. While regulations also influence opening dates, warming temperatures remain the primary disruptor, forcing companies to rethink traditional logistics strategies.

As ice road reliability declines, the risk of delays, accidents, and rising costs increases. Thinner ice reduces load capacities, requiring lighter shipments or more frequent trips, both of which drive up operational expenses. Faster thawing also shortens the safe transport window, disrupting supply chains and increasing reliance on alternative transportation.

The Role of Real-Time Temperature Monitoring in Ice Road Adaptation

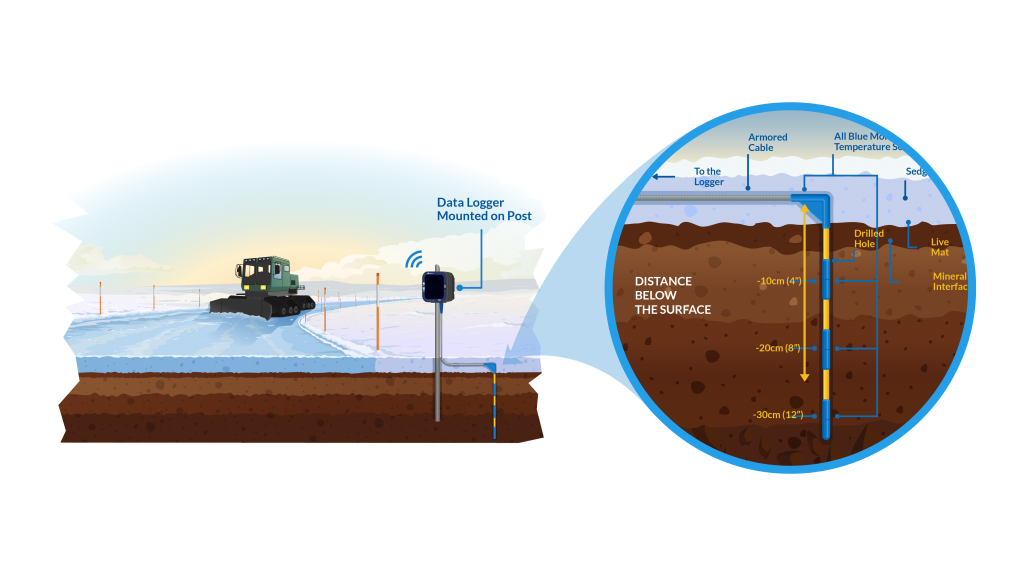

To manage these challenges, continuous temperature monitoring is becoming an industry best practice. Advanced digital temperature cables, remote data loggers, and cloud-based dashboards provide real-time insights into ice conditions, enabling teams to:

Predict Safe and Unsafe Conditions

Warmer winters are delaying freeze-up and shortening operational windows for ice roads. In November 2023, air temperatures in Alaska’s North Slope were observed to be about 2°C (3.6°F) higher than in November 2022, delaying ground cooling and pushing back ice road construction. Since ice road operations can only begin when ground temperatures reach -5°C at a depth of 30 cm, this warming trend caused delays of up to 11 days, according to analysis done with beadedstream’s Temperature Forecasting Tool.

With real-time subsurface temperature monitoring, operators can track freezing temperature fluctuations as they happen, allowing them to adjust schedules proactively instead of relying on outdated historical averages preventing costly delays.

Reduce Costs and Extend Ice Road Availability

Every additional day of ice road access translates to significant cost savings. Implementing real-time temperature monitoring allows companies to optimize transport schedules and reduce unnecessary site visits, thereby enhancing operational efficiency.

Enhance Safety and Environmental Compliance

By using remote data loggers, companies can provide real-time temperature data to regulatory agencies, ensuring compliance while minimizing environmental risks like fuel spills and wildlife disruptions.

beadedstream’s Approach

beadedstream’s real-time temperature monitoring solutions help Arctic industries make informed decisions about ice road safety. With digital temperature cables and remote data loggers, companies can track freeze progression with precision, reducing uncertainty in operational planning. On Alaska’s North Slope, one ice road operation used temperature sensors to manually predict target ground temperatures within a 6-7 hour window, enabling earlier and safer tundra access.

With continuous, high-resolution data, operators can visualize conditions through beadedcloud, beadedstream’s cloud-based dashboard. By integrating live sensor readings with historical trends, beadedcloud enables teams to anticipate ice road availability, reduce costly site visits, and make faster, data-driven decisions. Built for Arctic conditions, beadedstream’s technology provides the reliability needed to adapt to evolving freeze-thaw cycles, helping mining and energy companies operate more safely, efficiently, and sustainably.

If you want to learn more about how beadedstream’s monitoring solutions can improve your ice road operations, get in touch with our team today at contact@beadedstream.com.