Heap leaching is a widely used and cost-effective method for extracting valuable metals from low-grade ores. It offers a simpler alternative to crushing and grinding followed by flotation or other processes. However, maximizing metal recovery and ensuring efficient heap leach operations require close monitoring and control of various factors. One crucial aspect is temperature management within the heap leach pile.

This blog post delves into the heap leaching process, highlighting the significance of temperature monitoring. We’ll explore the challenges associated with traditional monitoring methods and how advancements in digital sensor technology are revolutionizing heap leach optimization.

Understanding Heap Leaching

Heap leaching involves stacking crushed or run-of-mine ore on an impermeable pad lined with a collection system. A leaching solution, often containing weak acids or bases, is then sprinkled over the heap. This solution dissolves the target metals from the ore particles as it percolates downwards. The pregnant solution, enriched with the dissolved metals, is collected at the bottom of the heap and further processed to recover the valuable metals.

Heap leaching is particularly suitable for recovering metals like copper, gold, uranium, and certain rare earth elements from low-grade ores that wouldn’t be economical to process using conventional methods (Zanbak, 2012). However, even within this seemingly simple process, factors like temperature play a crucial role in optimizing metal recovery, as we’ll explore further in the coming sections.

The Importance of Temperature Monitoring in Heap Leaching

Temperature plays a crucial role in the kinetics of the leaching process. Higher temperatures generally accelerate chemical reactions, enhancing the efficiency of metal extraction. However, extreme temperatures can lead to safety hazards and operational issues. Therefore, maintaining a consistent and optimal temperature range is essential for several reasons:

- Maximizing Metal Recovery: Optimal temperatures ensure that the leaching solution dissolves metals effectively, maximizing the yield from the ore. Research by Oediyani et al. (2019) achieved an impressive 89% nickel extraction at a specific temperature, highlighting the importance of maintaining an optimal range. Operating outside this range can hinder leaching effectiveness and reduce metal yields.

- Preventing Operational Disruptions: Sudden temperature changes can cause uneven leaching, leading to underperformance in some areas of the heap and potential structural instability (Zanbak, 2012).

Cold Region Considerations: In frigid climates, real-time temperature monitoring becomes even more critical. The leaching solution itself can become a threat if it freezes, significantly disrupting operations. By monitoring solution temperatures throughout the heap, operators gain valuable insights and can take proactive measures, such as deploying solution heaters, to prevent freezing and ensure a smooth-flowing leaching process.

- Reducing Chemical Usage: By monitoring temperature and adjusting the application of leaching solutions accordingly, mining operations can minimize the use of chemicals, reducing costs and environmental impact.

- Ensuring Environmental Compliance: Real-time monitoring helps ensure that the leaching process complies with environmental regulations by preventing leaks and contamination.

- Ensuring Safety: Extreme temperatures can pose risks to both equipment and personnel. Real-time monitoring helps in quickly identifying and mitigating these risks.

- Early Problem Detection: Temperature anomalies can indicate issues such as blockages or uneven distribution of the leaching solution. Early detection allows for prompt corrective actions, preventing costly downtime.

By closely monitoring and controlling temperature, mining operations can enhance efficiency, ensure safety, and comply with environmental standards, ultimately leading to more sustainable and profitable practices.

Challenges of Traditional Temperature Monitoring Methods

Traditionally, temperature monitoring in heap leach operations has relied on manual techniques or sparse sensor networks. These methods come with several limitations:

- Limited Data Points: Manual temperature measurements are often infrequent and provide only isolated data points. This makes it difficult to capture the overall temperature profile within the heap and identify potential issues.

- Labor-intensive: Manual readings require personnel to physically access various locations within the heap, which can be time-consuming and potentially hazardous.

- Safety Concerns: Entering a heap for temperature measurements can expose workers to safety risks associated with uneven surfaces, falling objects, or exposure to leaching solutions.

- Delayed Response: By the time temperature deviations are detected through manual methods, valuable time may be lost, potentially impacting metal recovery or leading to unforeseen problems.

Real-Time Temperature Monitoring with Digital Thermistor Strings

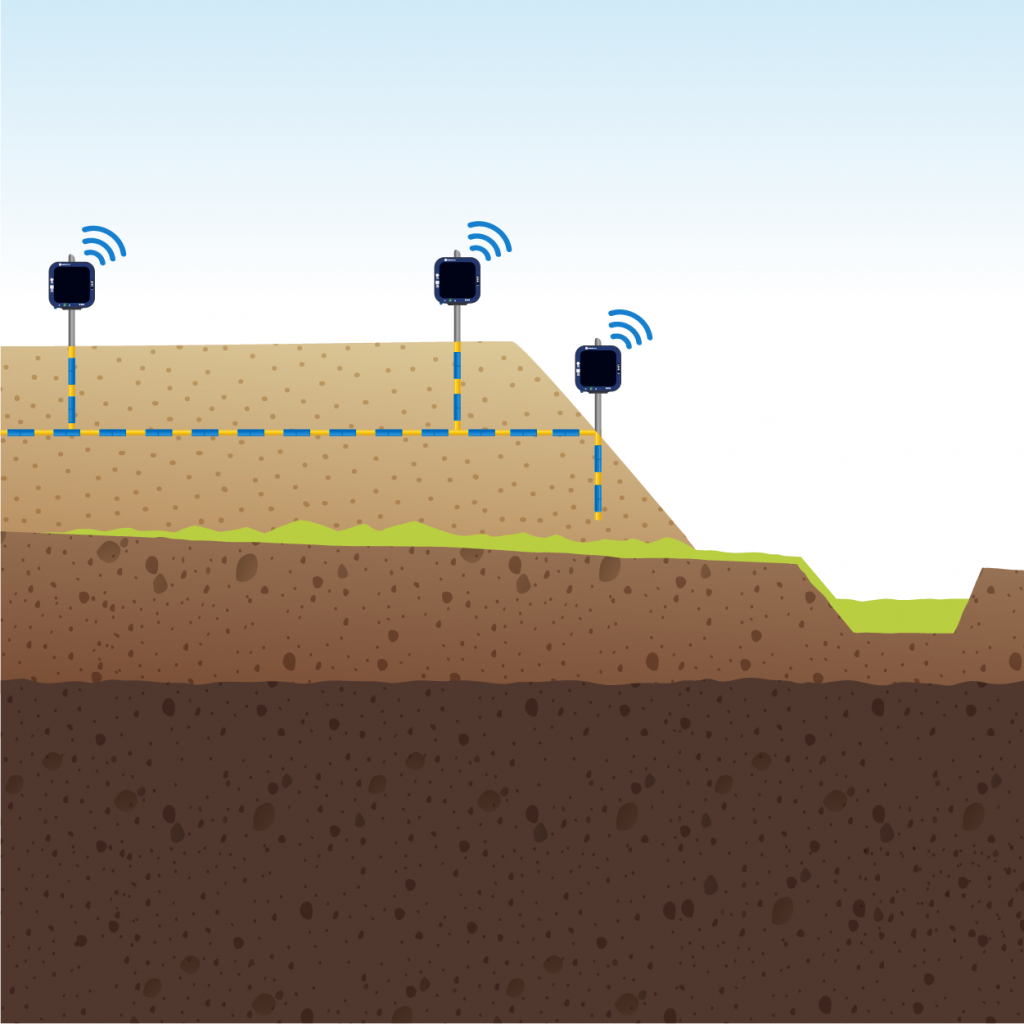

Recent advancements in sensor technology offer a more efficient and reliable solution for heap leach temperature monitoring. Digital thermistor strings, consisting of multiple temperature sensors embedded along a cable, can be strategically placed within the heap. These strings continuously collect temperature data at various positions, providing a comprehensive picture of the thermal profile within the heap.

The collected data is then transmitted via cable to data loggers, which can be positioned at safe and accessible locations. These loggers aggregate the data and transmit it to a cloud-based software platform in real-time. This allows for:

- Continuous Monitoring: Real-time temperature data provides a holistic view of the heap’s thermal conditions, enabling proactive management and optimization of the leaching process.

- Improved Safety: By eliminating the need for manual readings, digital thermistor strings minimize worker exposure to potential hazards within the heap.

- Data-Driven Decisions: The collected temperature data can be analyzed to identify trends, optimize irrigation patterns, and ensure consistent leaching performance across the entire heap.

- Predictive Maintenance: By monitoring temperature fluctuations, potential issues with pipes, pumps, or other infrastructure within the leach pad can be identified early on, allowing for preventative maintenance and minimizing downtime.

Benefits of Real-Time Temperature Monitoring

The advantages of implementing real-time temperature monitoring with digital thermistor strings extend beyond just improved process control and safety. Here are some additional benefits:

- Reduced Operational Costs: By optimizing irrigation and leaching processes based on real-time temperature data, mines can potentially reduce water consumption and leaching solution usage. This translates to significant cost savings over time.

- Improved Environmental Performance: Real-time monitoring allows for early detection of potential leaks or spills within the heap leach pad. This enables prompt corrective actions to minimize environmental impact.

- Enhanced Regulatory Compliance: Many regulatory requirements for heap leach operations focus on environmental protection and worker safety. Real-time temperature monitoring data can be used to demonstrate compliance with these regulations.

The Future of Heap Leach Optimization

As sensor technology continues to evolve and data analytics capabilities become more sophisticated, we can expect even greater advancements in real-time temperature monitoring for heap leach operations. Here are some potential future trends:

- Integration with Automation Systems: Real-time temperature data could be integrated with automated irrigation and leaching solution control systems. This would allow for dynamic adjustments based on the prevailing thermal conditions within the heap, further optimizing the process.

- Advanced Data Analytics: Machine learning algorithms could be employed to analyze historical and real-time temperature data to predict potential issues and recommend proactive maintenance strategies.

- Remote Monitoring and Management: Cloud-based platforms could enable remote monitoring and management of heap leach operations. This would allow for centralized oversight and decision-making, regardless of the physical location of the heap.

By embracing these advancements, mining companies can unlock the full potential of real-time temperature monitoring and achieve significant improvements in efficiency, safety, and environmental performance within their heap leach operations.

beadedstream’s Real-Time Monitoring Solution

beadedstream’s innovative solutions provide mining operators with the tools needed for effective real-time temperature monitoring. Their digital thermistor strings, combined with robust data loggers and intuitive cloud-based software, enable precise monitoring of heap leach operations. By integrating these technologies, mining companies can achieve optimal temperature conditions, enhancing metal recovery and operational efficiency while minimizing environmental impact.

Example of beadedstream digital thermistor strings and data loggers used in heap leach monitoring. Sensors are positioned at various depths and orientations, with cables running both horizontally and vertically to ensure comprehensive temperature tracking.

With extensive experience in cold region heap leach projects, beadedstream has demonstrated the value of their solutions in challenging environments. The risk of the leaching solution freezing is a significant challenge in cold climates, potentially disrupting operations. By meticulously monitoring solution temperatures, beadedstream helps engineers understand current conditions and implement mitigation strategies, such as solution heaters, to minimize operational impacts during winter. Their expertise ensures that even in the harshest conditions, mining operations can maintain efficiency and safety, further underscoring the importance of real-time temperature monitoring.

Conclusion

Heap leaching remains a crucial technique for extracting valuable metals from low-grade ores. Implementing real-time temperature monitoring with digital thermistor strings offers a powerful tool for optimizing this process. The benefits extend beyond just improved metal recovery, encompassing enhanced safety, reduced operational costs, and better environmental stewardship. As technology continues to evolve, the future of heap leach optimization holds immense promise for the mining industry. For more information on how beadedstream’s innovative solutions can enhance your heap leach operations, contact us at contact@beadedstream.com.