In the oil and gas industry, particularly in northern regions like Alaska, maintaining stable foundations for infrastructure is crucial. These regions are characterized by permafrost – ground that remains frozen for two or more consecutive years. Permafrost thaw, exacerbated by climate change, presents a significant challenge. The thawing and refreezing of permafrost can lead to ground movement, threatening the stability of foundations and pads. This can have severe economic consequences, causing costly repairs, delays, and even potential safety hazards. Without proper monitoring, buildings in permafrost regions face significant risks of ground instability, leading to potential structural failures.

Challenges of Building on Permafrost

Permafrost presents a unique set of challenges for construction and maintenance in the oil and gas industry. As temperatures fluctuate, the thawing and refreezing of permafrost’s active layer can lead to differential ground movement, affecting the stability of foundations and pads. This is particularly concerning for heavy industrial structures like pipelines, processing facilities, and storage tanks, which require unwavering support to ensure safety and operational efficiency.

According to the U.S. Geological Survey, approximately 24% of the Northern Hemisphere’s land surface is underlain by permafrost (Environmental System Science (ESS) PI Meeting Abstracts, 2018). The thawing of this permafrost due to climate change and ground disturbance from developments can lead to significant ground instability, posing risks to infrastructure worth billions of dollars.

Importance of Ground Temperature Monitoring

To mitigate these risks and safeguard valuable infrastructure investments, continuous ground temperature monitoring is essential. By closely tracking temperature changes throughout the permafrost layer, it becomes possible to anticipate and respond to potential thawing events, thereby maintaining the integrity of the foundation.

Digital Temperature Cables: A Game-Changer for Permafrost Monitoring

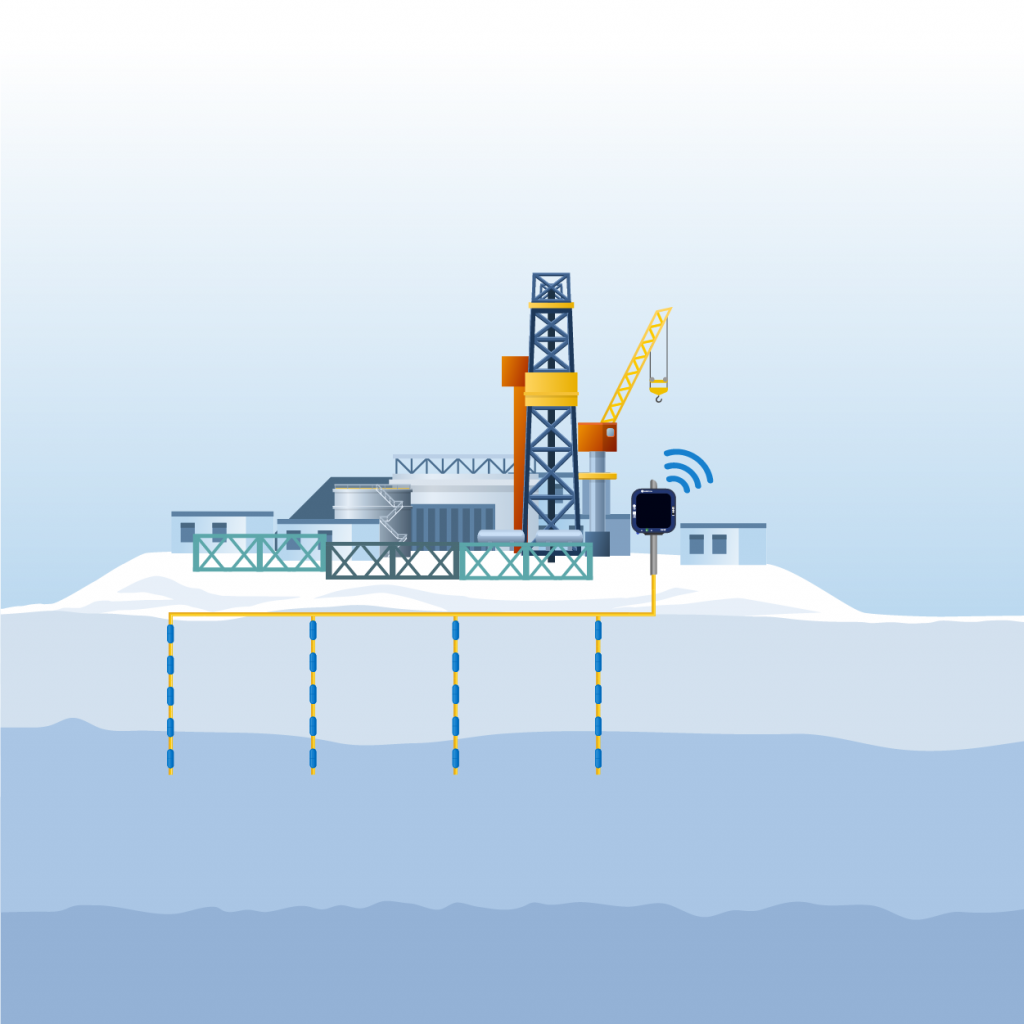

Advanced monitoring solutions, such as digital temperature cables, provide a game-changer for permafrost monitoring. These cables, embedded with multiple temperature sensors (thermistors) at various depths and positions, collect precise data on the thermal profile within the permafrost. This data is then transmitted via cable to robust data loggers positioned at safe and accessible locations. The data loggers aggregate the information and transmit it, in real-time, to a user-friendly cloud-based software platform, for access to data from anywhere on the planet.

For instance, beadedstream’s digital temperature cables were deployed at a critical infrastructure project in Deadhorse, Alaska (ASRC General Duty Shop). These cables provided real-time ground temperature monitoring across the permafrost foundation, ensuring stability for the new light and heavy-duty shops, offices, and wash bays. With eight strategically placed cables and satellite data loggers, the system facilitated continuous data collection and enabled immediate response to any temperature fluctuations.

Benefits of Real-Time Permafrost Monitoring with Digital Thermistor Strings

Implementing a comprehensive temperature monitoring system that utilizes digital temperature cables offers a multitude of benefits for oil and gas companies operating in permafrost regions. These benefits include:

Increased Safety and Stability: Continuous monitoring provides a holistic view of ground conditions, allowing for early warnings of potential ground thaw and enabling proactive measures to be taken, enhancing the safety and stability of infrastructure.

Enhanced Cost Efficiency: By identifying potential issues before they escalate into major problems, companies can avoid costly repairs and infrastructure failures. Additionally, real-time data allows for optimized maintenance scheduling, minimizing downtime and resource allocation.

Streamlined Regulatory Compliance: Precise monitoring data facilitates adherence to environmental and safety regulations. This not only helps avoid hefty fines but also strengthens a company’s reputation for responsible operations.

Data-Driven Decision Making: Real-time temperature data empowers informed decision-making. Maintenance can be scheduled based on actual ground conditions rather than estimates, optimizing resource allocation and minimizing downtime. Integrated data analysis and visualization tools within the cloud-based software platform provide actionable insights for proactive management.

Improved Environmental Stewardship: Early detection of potential leaks or spills associated with foundation issues allows for swift corrective actions, minimizing environmental impact. Real-time temperature monitoring allows for early detection of permafrost thaw that could compromise the structural integrity of pipelines and other infrastructure. By identifying and addressing potential ground movement before it occurs, companies can proactively prevent leaks associated with foundation issues, minimizing environmental impact and ensuring regulatory compliance.

Conclusion

The stability of foundations in permafrost regions is a critical concern for the oil and gas industry. Real-time ground temperature monitoring, particularly with advanced solutions like beadedstream’s digital temperature monitoring system, plays a pivotal role in safeguarding infrastructure stability and ensuring operational efficiency. By investing in reliable temperature monitoring technologies, companies can ensure safety, minimize costs, comply with regulations, and contribute to a more sustainable future in permafrost environments.

To learn more about how beadedstream’s solutions can benefit your operations, reach us at contact@beadedstream.com or visit our website and explore our range of temperature monitoring technologies.